See all Innovation Awards

FEDIT – CIT UPC – One step ahead

EARTO Innovation Awards 2019 – Impact Expected Category

Second Prize

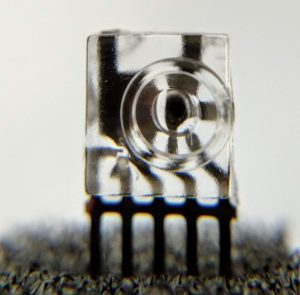

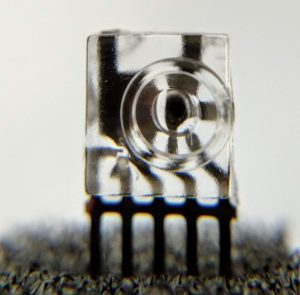

Photonic integrated circuits (PIC) accommodating multiple optical functions are already all around us in lighting, communication, health, industry and transport applications. These light-based chips have even greater potential – and could even topple electronics – if current manufacturing time, component positioning errors and associated costs could be reduced. CIT UPC/CD6 has developed a new methodology, PICEO, for manufacturing PICs which overcomes all these drawbacks by using optical quality micro-injection techniques with thermoplastic materials. This new technology for encapsulating the active optical elements in PIC devices and to embed the optical elements of the PIC to provide optical functionality opens up innovative design possibilities for enhanced functionality and longevity and in so doing redefines the optical design and manufacturing landscape. An advanced PICEO manufacturing facility will open in 2020 to capitalise on this disruptive innovation by producing high added-value products for mass market applications across the industrial spectrum.

The new PICEO manufacturing process

reduces costs and energy consumption by 50%

The old manufacturing process

The old manufacturing process used to take

4-5 hours – now it’s just

30 seconds

The photonic integrated circuits market

The photonic integrated circuits market is forecast to grow from

€267B to more than

€1,300B by 2022

By 2024,

the project’s return on investment is expected to be

€5.8 for each Euro invested

Limiting circuit performance

Encapsulation is one of the most important elements of the PIC manufacturing process, protecting optical parts, enabling connectivity and facilitating operation and installation procedures. It is also one of the most costly, accounting for 60% of production costs. Currently, encapsulation uses mould injection of thermosetting plastics, which has several limitations. These include a four-to-five hour curing stage which causes production bottlenecks and extra energy consumption, time and cost. This method also limits the geometries of optical parts, which affects functionality, and takes several steps to align components, which can result in suboptimal precision and poor final performance.

Redefining the production process

The UPC Technology Center – CIT UPC, EARTO member through Fedit, aimed to find a way to automate component positioning, enable in-line validation of component behaviour and reduce the cost of the curing process. The result is PICEO, a micro-injection machine for PIC encapsulation based on moulding with thermoplastics that allows to embed the secondary optical elements at the same moment of the encapsulation. PICEO simplifies the production process, enabling multiple optical elements to be manufactured and assembled in one step for the first time. It also fulfils an unmet market need for lower production volume and allows the use of free-form optical surfaces, which improves performance and efficiency by 8-10%. This in turn reduces energy demand for the same output of light and increases product lifetime.

Competing in the global market

When this technology reaches the market in 2020 it will initially be focused on key markets including LED lighting, information and communication technology, sensors and photovoltaics, which account for almost 70% of total market income – around €139M. The plan is to generate revenue through three streams: the sale of manufacturing equipment, maintenance services and component royalties. As the only low-cost, high-quality process of its kind in the world, PICEO will help Europe compete in the global market, even in regions where labour prices are lower, and significantly contribute to maintaining the current double-digit growth rate of the PIC industry.

More information about this innovation

Fedit

Fedit is a Spanish association of research and technology organisations whose main mission is to boost and encourage innovation, technological development and private research.

www.fedit.com

The UPC Technology Center (CIT UPC) is a non-profit entity, attached to the Universitat Politècnica de Catalunya (UPC) and focussed on applying university research capabilities to innovation in business. CD6 is a research group within CIT UPC.

www.cit.upc.edu

© Photos Credit: Fedit, CIT UPC

Photonic integrated circuits (PIC) accommodating multiple optical functions are already all around us in lighting, communication, health, industry and transport applications. These light-based chips have even greater potential – and could even topple electronics – if current manufacturing time, component positioning errors and associated costs could be reduced. CIT UPC/CD6 has developed a new methodology, PICEO, for manufacturing PICs which overcomes all these drawbacks by using optical quality micro-injection techniques with thermoplastic materials. This new technology for encapsulating the active optical elements in PIC devices and to embed the optical elements of the PIC to provide optical functionality opens up innovative design possibilities for enhanced functionality and longevity and in so doing redefines the optical design and manufacturing landscape. An advanced PICEO manufacturing facility will open in 2020 to capitalise on this disruptive innovation by producing high added-value products for mass market applications across the industrial spectrum.

Photonic integrated circuits (PIC) accommodating multiple optical functions are already all around us in lighting, communication, health, industry and transport applications. These light-based chips have even greater potential – and could even topple electronics – if current manufacturing time, component positioning errors and associated costs could be reduced. CIT UPC/CD6 has developed a new methodology, PICEO, for manufacturing PICs which overcomes all these drawbacks by using optical quality micro-injection techniques with thermoplastic materials. This new technology for encapsulating the active optical elements in PIC devices and to embed the optical elements of the PIC to provide optical functionality opens up innovative design possibilities for enhanced functionality and longevity and in so doing redefines the optical design and manufacturing landscape. An advanced PICEO manufacturing facility will open in 2020 to capitalise on this disruptive innovation by producing high added-value products for mass market applications across the industrial spectrum.

The new PICEO manufacturing process reduces costs and energy consumption by 50%

The new PICEO manufacturing process reduces costs and energy consumption by 50%

The old manufacturing process used to take 4-5 hours – now it’s just 30 seconds

The old manufacturing process used to take 4-5 hours – now it’s just 30 seconds

The photonic integrated circuits market is forecast to grow from €267B to more than €1,300B by 2022

The photonic integrated circuits market is forecast to grow from €267B to more than €1,300B by 2022  By 2024, the project’s return on investment is expected to be €5.8 for each Euro invested

By 2024, the project’s return on investment is expected to be €5.8 for each Euro invested

Fedit is a Spanish association of research and technology organisations whose main mission is to boost and encourage innovation, technological development and private research.

www.fedit.com

The UPC Technology Center (CIT UPC) is a non-profit entity, attached to the Universitat Politècnica de Catalunya (UPC) and focussed on applying university research capabilities to innovation in business. CD6 is a research group within CIT UPC.

www.cit.upc.edu

Fedit is a Spanish association of research and technology organisations whose main mission is to boost and encourage innovation, technological development and private research.

www.fedit.com

The UPC Technology Center (CIT UPC) is a non-profit entity, attached to the Universitat Politècnica de Catalunya (UPC) and focussed on applying university research capabilities to innovation in business. CD6 is a research group within CIT UPC.

www.cit.upc.edu