ITRI – LCD waste recycling system

EARTO Innovation Awards 2020 – RTOs International Network (RIN)

Liquid Crystal Displays (LCDs) have replaced Cathode Ray Tubes (CRTs) as the main display devices in recent years. To satisfy the increasing demands, billions of LCDs are manufactured annually. As more LCDs are produced and used, the amount of LCD waste is increasing at an alarming rate. Current treatment technologies can disassemble LCD into multiple components and recycle them according to their materials. However, there is no suitable model for treating LCD panels. Research has repeatedly shown the harmfulness of liquid crystal, indium and other heavy metals which LCD panels contain. As a result an increasing number of countries have classified LCD panels as hazardous waste. Because of this, future processing of LCD panel waste will require on-site burial, burning, or physical disposal, not only increasing processing costs, but also causing environmental damage. This is a huge problem. That is why this recycling technology for waste LCD panels is a kind of revolutionary breakthrough.

The pilot plant handles 3T of waste LCD panels daily, with a liquid crystal recycling rate of 100%, indium recovery rate of more than 90% and glass recycling rate of 100%

Around 1M tons of LCD panel are discarded in the world every year and 1,000 sets of LCD waste recycling system are required for recycling

Around 1M tons of LCD panel are discarded in the world every year and 1,000 sets of LCD waste recycling system are required for recycling

The global annual output value of LCD waste panel material recycling is estimated at $3B

ITRI has assisted Taiwan LCD makers in recovering and reusing 100 tons of liquid crystals, achieving a cost reduction benefit of about $700M

Recycling of liquid crystals

Liquid crystal is the main component of LCD. It is a chemical with a high unit cost, high stability and low biodegradability. While the harmfulness of liquid crystal is uncertain, its structure contains a large volume of benzene rings, fluorine, chlorine, and bromine, which, if buried, may seep into subterranean water systems and impact ecosystems. Physical processing entails breaking down LCD panels and adding them to cement or concrete, which does not remove liquid crystals and heavy metals from the panels, so they may still enter and harm the environment following rain or washing. Based on environmental and economic considerations, the liquid crystal in the LCD panel should be reused.

Separation, purification and recycling

To prevent the pollution caused by waste LCD panel disposal, and to control processing costs, ITRI thoroughly analysed the characteristics and reusability of each material contained in LCD panels, and designed a logical separation procedure according to the associations between each material, first separating liquid crystal, indium, and glass, and then developing purification technology for each material which enables the reuse of these materials. Liquid crystal can be reused in new LCDs or liquid crystal smart windows. Indium can be refined as the raw material of sputtering targets. Glass can become a humidity-controlling green building material or heavy-metal adsorption material.

Protecting the environment worldwide

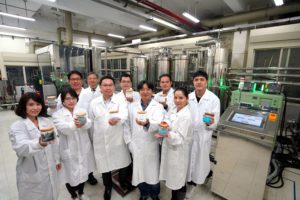

ITRI’s pilot plant can treat 3 tons of waste LCD panel per day of operation, producing 3 kilograms of liquid crystal, 750 grams of indium, and about 2,550 kilograms of glass, which can be reused as humidity-controlling green building material or heavy-metal adsorption material. ITRI’s team uses the pilot plant for technical verification of on-line scrap LCD panels and end-of-life LCD panels. ITRI can build the LCD panel processing center for LCD manufacturers and e-waste recycling companies.

ITRI is a leading research and technology institute with more than 6,000 researchers. Its mission is to drive industrial development, create economic value, and enhance societal well-being through technology R&D. Founded in 1973, it pioneered in IC development and continues to nurture emerging tech ventures and deliver its R&D results to industries.

© Photos Credit: ITRI

< Previous Next >